Gold Ore Processing Plant, Crushing Quartz Hardrock Gold

#0183;#32;This is a video showcasing our 1 ton per hour complete, chemical free, gold ore gravity processing plant. This system is specifically designed for the small

WhatsApp)

WhatsApp)

#0183;#32;This is a video showcasing our 1 ton per hour complete, chemical free, gold ore gravity processing plant. This system is specifically designed for the small

Quartz Ore Mining Processes. May 01 2014 a number of minerals pose serious hazards to human beings and the environment using research compiled by dr gordon brown of stanford university lists the eleven minerals with the most catastrophic consequences for human health crocidolite als,Quartz Ore Mining Processes. Get Price . Quartz Minerals Education Coalition. Quartz quartz is one of the most

Quartz Magnetic separation amp; flotation process: Attrition is applied to clean the surface of the quartz particles. Thereby fine particles attached to quartz surfaces, clay minerals or iron oxide coatings, are liberated, which allows the subsequent physical separation including magnetic separation and flotation process.

As a pretreatment method before the ore separation, the washing, classifying and desliming are applied earlier and widely in the quartz washing plant, but this quartz mining process doesnt have the obvious removal effect for the thinfilm iron and adhesive impurity minerals on the surface of quartz stone.

Quartz is one of the most common minerals in the Earths crust. As a mineral name, quartz refers to a specific chemical compound (silicon dioxide, or silica, SiO 2), having a specific crystalline form (hexagonal).It is found is all forms of rock: igneous, metamorphic and sedimentary.

22/07/2018#0183;#32;Here''s a video demonstrating my process for recovering fine gold from quartz ore which I hiked out from the mountains. This sample was taken out of the north...

Processes Involve In Iron Ore Mining. Mining industry careersfluorospar and highgrade iron oreining requires a network of shafts and tunnels which have to be designed according to geological information obtained from drillinghafts have to be designed to handle the required volume of air to produce an environment that is acceptable by world standards and to handle the.

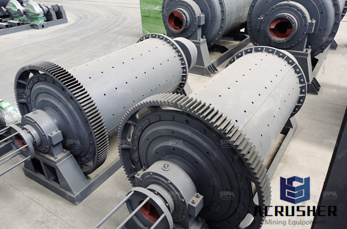

Crushing is normally carried out on quot;runofminequot; ore, while grinding (normally carried out after crushing) may be conducted on dry or slurried material. In comminution, the size reduction of particles is done by three types of forces: compression, impact and attrition. Compression and impact forces are extensively used in crushing operations while attrition is the dominant force in grinding

These pockets are filled with gold, heavy ore, and quartz. Since the costs of exploration and removal of gold from rock can be high, large companies are created in order to raise the money necessary for the development of hard rock mines. This is different from the solitary individual or small group associated with placer mining (see Lode vs. Placer Mining for a discussion of the

quartz ore mining processes Caldera Machinery. quartz ore process. Quartz. Whenever sulphide orquartzis associated with gold the resultant gold ores are typically amenable to a certain degree of particle sorting And in the case of the complex blend ofquartzassociated with gold the preconcentration of theoreby means of sensorbasedoresorting during the early stages of the productionprocesscan

Although at this time alluvial mining was the primary method of gold recovery, the Tambaroora fields also supported the earliest attempts at reef mining in Australia, over fifteen years before the reef mining boom of the 1870s. The Quartz Roasting Pits Complex is one of the oldest goldrush sites in Australia and represents one of the first attempts to process gold bearing ore. It also

Fluorite ore beneficiation process . fluorite beneficiation . The quartz type is mainly composed of fluorite (with a content of up to about 85%) and quartz. There are only a small amount of calcite, barite and sulfide. The key to its selection is mainly to reduce the silicon content of the concentrate. To separate quartz and fluorite, the appropriate grinding fineness must be

According to the degree of ore oxidation, the type of gold ore can be divided into primary (sulfide ore) ore, partially oxidized (mixed) ore and oxidized ore. Here are the gold mining processes used for five types of gold ore. 1. Poor sulfide gold mining process. This kind of gold ore is mostly quartz vein type gold ore, also includes multiplex

Flotation and subsequent processes refractory ore processing The essential requirements for a good gold recovery are adequate cyanide and oxygen for thiourea or thiosulphate are their high leaching rates that can reach 250mg/cm2 per primary ore pyrite as well as in supergene ore quartz and limonite . .

How to Find Quartz Stones #183; How to Process Gold Ore Quartz mining had existed in Arkansas since the 1800s, but Stanley believed that only a small amount... Read More. Quartz reef mining . Processing[edit]. The gold was The quartz was then crushed into a fine dust by stamping batteries in a stamp mill. A stamp battery... Read More. Mining: The Hard Rock Mining Process Mining the

Quartz Ore Mining Processes. May 01 2014 a number of minerals pose serious hazards to human beings and the environment using research compiled by dr gordon brown of stanford university lists the eleven minerals with the most catastrophic consequences for human health crocidolite als,Quartz Ore Mining Processes.

Quartz stone sand production line equipment design. the sand making process of ore materials Material: quartz stone. Mohs hardness: 56. Density: //cm3. Quartz stone is a hard, wearresistant, chemically stable silicate mineral. Its main component is silica. Process Of Making Silica Sand From Quartz Stone. Process Of Making Silica Sand From Quartz Stone Albumt. We can provide our

This quartz mining process overcomes the shortcomings of secondary contamination of iron caused by rod friction washing and low yield. In the practice, the selection of the quartz mining processes and flows is often determined based on the nature of quartz stone, conditions of the quartz processing plant, investment budget.

WhatsApp)

WhatsApp)